Waste Plastic Recycling Crusher Machine Plastic Grinder Machine

Basic Info.

| Model NO. | BXD1000 |

| Raw Material | HDPE |

| Structure | Tangential Feed |

| Knife Classification | Flat Knife Crusher |

| Knife Roll | Solid Knife Roller |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure V |

| Video Outgoing-Inspection | Provided |

| Keywords | Plastic Crusher |

| After Warranty Service | Video Technical Support, Online Support, Spare PAR |

| Product Name | Plastic Crusher Machine |

| Warranty of Core Components | 1 Year |

| Function | Crushing Washing Drying Plastic |

| Typ | Plastic Crusher Machinery Price |

| Usage | Plastic Crusher Line |

| Transport Package | Film/Wooden Package |

| Specification | 4200*2350*4870 |

| Trademark | Boxin |

| Origin | Jiangsu |

| HS Code | 8477800000 |

| Production Capacity | 1000kg/H |

Packaging & Delivery

Package Size 850.00cm * 500.00cm * 500.00cm Package Gross Weight 3000.000kgProduct Description

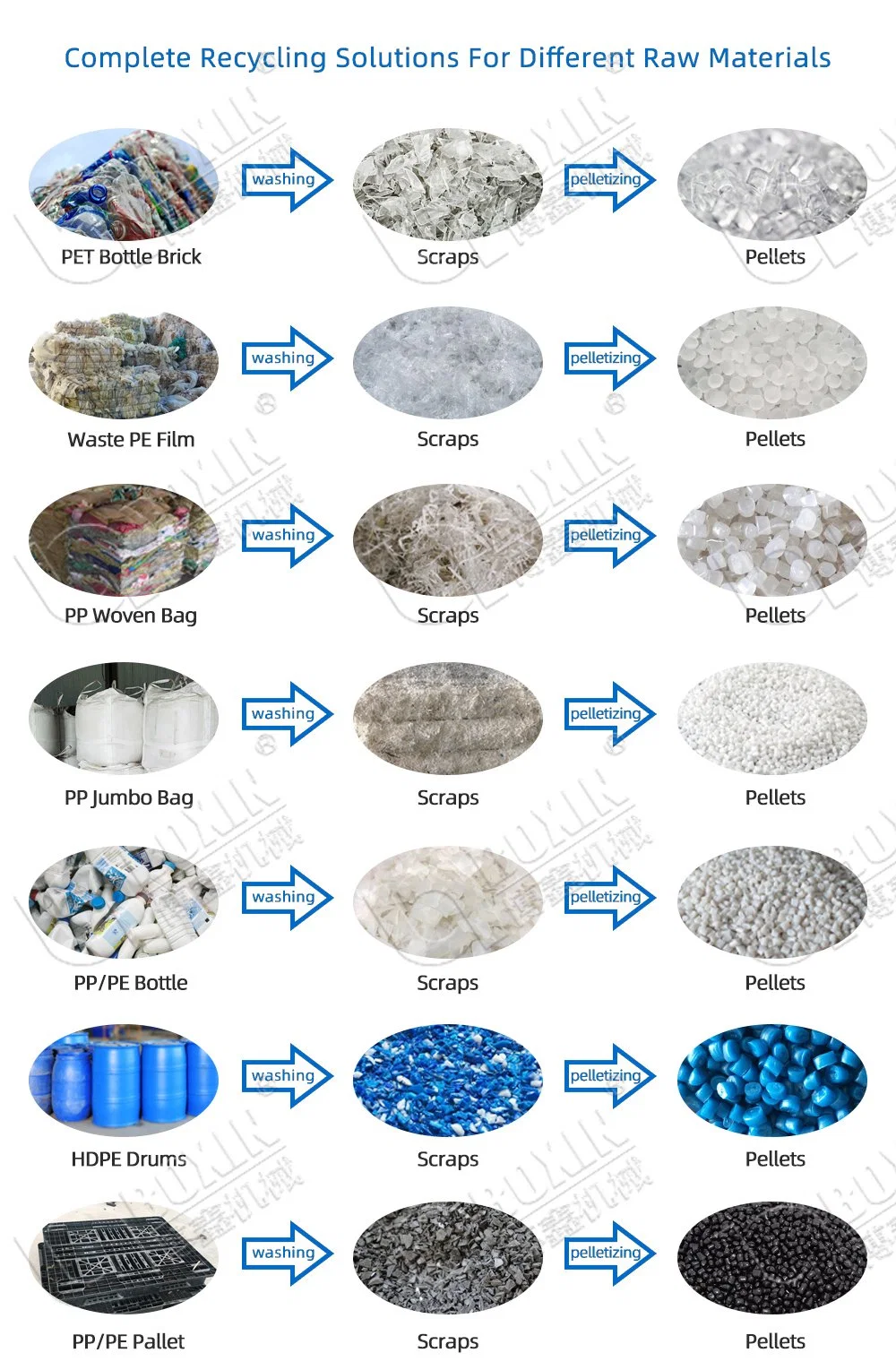

Welcome to BOXINCompany ProfileBOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.Product DescriptionPet Bottle Crusher MachinePlastic bottles and films grinder/shredder series is suitable for PET/PP/PE Bottles, ABS/PS Plastic Crusher Used for the PET bottle, Plastic bottle, buckets, hollow containers, and so on plastic; Its with special structure design, will have more capacity with less power consumption.

If you cannot find the similar product you want, you can send us some photos. Click 'Send Inquiry/Contact Supplier'

| Product Paramenters | ||||

| Model | BXD-800 | BXD-1000 | BXD-1200 | BXD-1400 |

| Output (KG/H) | 400-600 | 900-1200 | 1400-1600 | 1800-2100 |

| Motor power(KW) | 37 | 55-75 | 90-110 | 110-132 |

| Number of rotary knives(pieces) | 6 | 6(10) | 10 | 10 |

| Number of fixed knives (pieces) | 4 | 4 | 4 | 4 |

| Main shaft rotation diameter (mm) | Φ500 | Φ650 | Φ750 | Φ750 |

| Dimensions | 3000*2500*4160 | 3100*2650*4830 | 3700*3060*5300 | 3800*3300*5430 |

>>> Optimized crushing chamber, with help of the hydraulic controlling open and close, it's easy to clean the inner chamber and rapidly replace parts. STABLE POWERTRAIN

>>> The drive motor and gear box are of European brands, with high efficiency of energy utilization for long-term stable running. UNIFORM GRINDING

>>> We have more than twenty different knife designs such as double-shear V-shaped cutting. They can achieve uniform particle size and less dust after crushing. Modular cutting chamber. Select suitable knives and screen according to material characteristics.>>> Alloy steel rotary and fixed knives are made by European supplier. CUTTING CHAMBER

>>> Bolt connection steel structure, 2 positive and negative double-edged stator knives are installed in the box, which can be reground and adjusted multiple times.>>> The hinged screen frame is convenient for disassembly and assembly of the screen, and can be installed and removed through a separate door without tools.

1. YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

·BOXIN is original manufacturer.·If you interested in our products and we can fulfill your request , you may pay a visit to BOXIN Factory.·The meaning of visiting supplier, since seeing is believing, BOXIN Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.2. SEE BOXIN MACHINE HOW TO ENSURE THE QUALITY ·In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.·Each component before assembly needs strict control by inspecting personnel.·Each assembly is in charge by a master who has working experience for more than 15 years·After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.3. THE AFTER-SALE SERVICE OF BOXIN MACHINERY·After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.·After the commissioning, we will package the equipment by the standard export package for shipment.·According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.·Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.